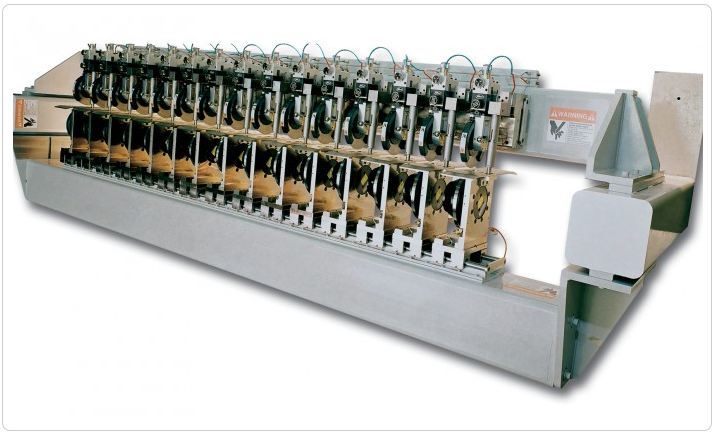

Used in applications that involve multiple slits and need the best quality cut, Tidland’s durable and reliable Hitchiker Linked Slitting System drastically reduces web-out slitter setup time and improves slit quality. The Hitchiker allows repositioning of knifeholders and anvil rings simultaneously, maintaining the critical blade-to-anvil relationship. This affordable slitting system is available in two sizes, and is capable of handling smaller systems with 2-3 knives, as well as larger systems. The Hitchiker retrofits easily to most machines, accommodating virtually any web width and any number of slits.

Mill-Duty durability

Increased slitter set-up accuracy and repeatability

Faster order changes

Ease of maintenance

Easy retrofit

Optional Equipment (may alter dimensions):

Gear reducer (minimum slit widths are increased)

Special motors based on speed requirements

Custom web support platens

Support frames

Trim Chute

| Class II | Class III | |

| Carriages | ElectrolessNickelPlated | |

| Knife Blade | 150 mm (5.91 inches) | 200 mm (7.87 inches) |

| Anvil Blade | 190 mm (7.48 inches) | 250 mm (9.84 inches) |

| Minimum Slit Width | 133 mm (5.25 inches) | 152 mm (6 inches) |

| Speed Range (all applications)* | 114 - 1,463 meters/minute (375-4,800 feet/minute) |

163 - 3,049 meters/minute (535 - 10,000 feet/minute) |

| Knifeholder Air (filtered, regulated dry air) | 4.1 - 5.2 bar (60 - 75 psi) | |

| Carriage Brake Air (filtered, dry air) | 5.5 - 6.9 bar (80 - 100 psi) | |

| AC Motor Ratings | 0.11 - 0.96 kW (1/8 to 1-1/4 HP) | |

| Power Requirements | 230 - 460 VAC 3-Phase | |

*Maximum speed is dependent on application and material. Lower speeds are possible with gear reducer.