E-Catalog > ROTARY LOBE PUMP > ROTARY LOBE PUMP JN-2-B-122

Product Detail :

ROTARY LOBE PUMP JN-2-B-122 APPLICATIONS

◆FOOD STUFFS

Jams, chocolate, syrups, sauces, tomato ketchup, batters, stews,sausage meats, eggs, fats, gelatin, soup, liquid sugar, molasses,honey, vinegar, preserves, soya sauce, peanut butter, jelly,chutney, mincemeat, olive oil, palm oil, chicken paste, coconut oil,cod oil, ketchup, maple syrup, marmalade, salad dressing, flavoring, pulp.

◆DAIRY PRODUCTS

Milk, curdled milk, yogurt, whey, cheese, curd, butter, margarine,oils, creams, cheese whey, mousse, custard cream cheese, pudding.

◆Beverages

Beer, wines, alcohol, syrups, yeast, wort, spirits, juices, cordials,minerals, tea, water, coffee liquor, cordials, cranberry juice.

◆PAPER & CHEMICALS

Acids, alkaline, soaps, paints, dyes, lacquers, resins, lubricants,solvents, black liquors, adhesives, latex, waxes, coatings, pastes,nail polish, mascara

◆PHARMACEUTICALS

Cream, gels, serums, disinfectants, lotions, shampoos, perfumes,soaps, toothpaste, vaccines, Vaseline, antibiotics, glucose,lodine ointment, perfumes.

ROTARY LOBE PUMP JN-2-B-122 FEATURES

◆ High precision non-contact lobes and no metallic inclusions.

◆ Materials of construction:Low carbon stainless steel pump body and cover.

◆ Wide range of rotors for all applications.

◆ High vacuum ability.

◆ Easy to clean – CIP or manually.

◆ Run-dry with mechanical seal.

◆ No damage in transferring products.

◆ Keep a stable durability for a long operation.

◆ Metering discharge low noise & pulsation.

◆ Low cost for a charge of spare parts.

◆ Smooth surfaces of both rotor case and front cover.

◆ Easy to disassemble/assemble.

◆ Shaft is retained by the front bearing part that has the least impact from thermal expansion.

◆ Short gearbox makes the high volumetric ration achievable.

◆ Rotating shaft and its receiving box has a very processing precision and extremely large volumetric efficiency.

◆ Gearbox is ease of maintenance.

◆ The interior of pump casing has been machined a structure of totally positive displacement for liquid application. ◆ Timing gear is in a conical locking structure, ease of timing adjustment.

◆ Double-end-face bearing, with high-precision and enhancing durability.

◆ Gearbox is made of rigid cast iron.

◆ Lubricating oil or grease is applied to lubricate the bearing and timing gear.

◆ Stainless steel shaft of high strength used, discharging high capability.

ROTARY LOBE PUMP JN-2-B-122 OPERATING PRINCIPLES

Rotary lobe pumps are similar to external gear pumps in operation in that fluid flows around the interior of the casing. Unlike external gear pumps, however, the lobes do not make contact. Lobe contact is prevented by external timing gears located in the gearbox. Pump shaft support bearings are located in the gearbox, and since the bearings are out of the pumped liquid, pressure is limited by bearing location and shaft deflection.

1. The lobes, they create expanding volume on the inlet side of the pump. Liquid flows into the cavity and is trapped by the lobes as they rotate.

2. Liquid travels around the interior of the casing in the pockets between the lobes and the casing --it does not pass between the lobes.

3. Finally, the lobes forces liquid through the outlet port under pressure.

Rotary lobe pumps are frequently used in food applications because they handle solids without damaging the product. Particle size pumped can be much larger in rotary lobe pumps. Since the lobes do not make contact, and clearances are not as close as in other pumps, this design handles low viscosity liquids with diminished performance. Loading characteristics are not as good as other designs, and suction ability is low. High-viscosity liquids require reduced speeds to achieve satisfactory performance.

|

A=AXIAL clearance lobe / front cover |

|

| Rotors in stainless steel clearances |

|

Pump Type |

A |

B |

C |

D |

|

JN-1-L |

0.1±0.02 |

0.1±0.02 |

0.1±0.02 |

0.1±0.02 |

| JN-2-L | 0.125±0.03 | 0.125±0.03 |

0.1±0.03 |

0.1±0.03 |

| JN-3-L |

0.125±0.035 |

0.125±0.035 | 0.1±0.035 | 0.1±0.035 |

| JN-4-L | 0.15±0.04 | 0.15±0.04 | 0.12±0.04 | 0.12±0.04 |

| JN-5-L | 0.15±0.045 | 0.15±0.045 | 0.15±0.045 | 0.15±0.045 |

Dimensions in mm

ROTARY LOBE PUMP JN-2-B-122 DIMENSIONS

|

|

JN-2-B-122 |

|

A |

216 |

| B | 108 |

| C | 234 |

| D | 93 |

| F(in/out) | 38 |

| G | 23 |

| H | 142 |

| I | 186 |

| J | 11 |

| K | 323 |

| L | 250 |

| M | 50 |

| O(Wide) | 5 |

| O(Length) | 2.5 |

| P | 19 |

| Q | 137 |

| R | 104 |

| T | 150 |

| V | 54 |

| W | 83 |

| Weight(kg) | 28 |

ROTARY LOBE PUMP JN-2-B-122 THEORETICAL PUMP-OUT

|

Model |

JN-2-B-122 |

| Theoretical pump-out (cc/1R) | 122 |

ROTARY LOBE PUMP JN-2-B-122 PARTS LIST

|

Item |

Part No. | Part Name | Q’ty | Item | Part No. | Part Name |

Q’ty |

|

1 |

1 | GEAR BOX | 1 | 27 | DP-2 | DOWEL PIN |

2 |

| 2 | BR-2 | BEARING | 4 | 28 | 6-3 | INNER SEAL | 2 |

| 3 | 4-2 | SLEEVE | 2 | 29 | SS-3 | STAINLESS SCREW | 4 |

| 4 | 9-1-R | DRIVE SHAFT | 1 | 30 | SR-1 | STAINLESS SPRING | 8 |

| 5 | 9-1-L | LAY SHAFT | 1 | 31 | OR-3 | O-RING | 2 |

| 6 | 5-3-A | SLEEVE | 2 | 32 | 6-2 | GALVANIZE SCREW | 2 |

| 7 | 5-3-B | SLEEVE | 2 | 33 | OR-2 | O-RING | 2 |

| 8 | BR-1 | BEARING | 4 | 34 | 6-1 | SEAL SEAT | 2 |

| 9 | AW | OCKING WASHER | 2 | 35 | SSP-1 | STAINLESS SPRING PINS | 6 |

| 10 | AN-L/AN-R | LOCKING NUT | 1 | 36 | 8-1-B | STUD BLT | 4 |

| 11 | 5-1 | COVER | 2 | 37 | DP-1 | DOWEL PIN | 2 |

| 12 | SC | POWER LOCK | 2 | 38 | 10 | ROTOR CASE | 1 |

| 13 | 5-2-L (R) | GRAR | 2 |

39 |

SS-1 | STAINLESS SCREW | 2 |

| 14 | AS-2 | ALLOY SCREW | 8 | 40 | ABCDE | ROTOR | 2 |

| 15 | 4-1 | SEAL SEAT | 1 | 41 | 9-3-R | ROTOR NUT | 1 |

| 16 | AS-1 | ALLOY SCREW | 2 | 42 | 9-3-L | ROTOR NUT | 1 |

| 17 | DRK-1 | DOUBLE ROUND KEY | 1 | 43 | OR-1 | R-RING | 1 |

| 18 | SE-2 | SEAL | 1 | 44 | 13 | PUMP COVER | 1 |

| 19 | OR-4 | O-RING | 2 | 45 | 8-1-A | CAP NUT | 4 |

| 20 | OR-7 | O-RING | 1 | 46 | OR-5 | O-RING | 2 |

| 21 | 7 | GEARBOX COVER | 1 | 47 | 2 | INLET/OUTLET | 2 |

| 22 | GS-1 | GALVANIZE SCREW | 8 | 48 | SS-2 | STAINLESS SCREW | 8 |

| 23 | SE-1 | SEAL | 2 | 49 | HW-1 | SUSPENSION LOOP | 1 |

| 24 | OR-6 | O-RING | 2 | 50 | HW-2 | OIL FILL | 1 |

| 25 | 3 | COVER | 2 | 51 | HW-3 | OIL LEVEL GLASS | 1 |

| 26 | GS-2 | GALVANIZE SCREW | 8 | 52 | HW-4 | PLUG | 1 |

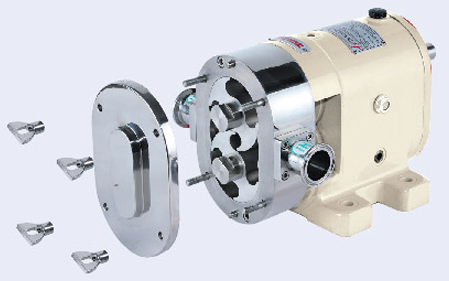

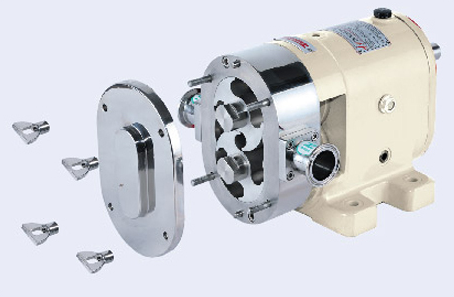

ROTARY LOBE PUMP JN-2-B-122 EXPLODED DRAWING